22nd Aug 2022

Behind the Seams

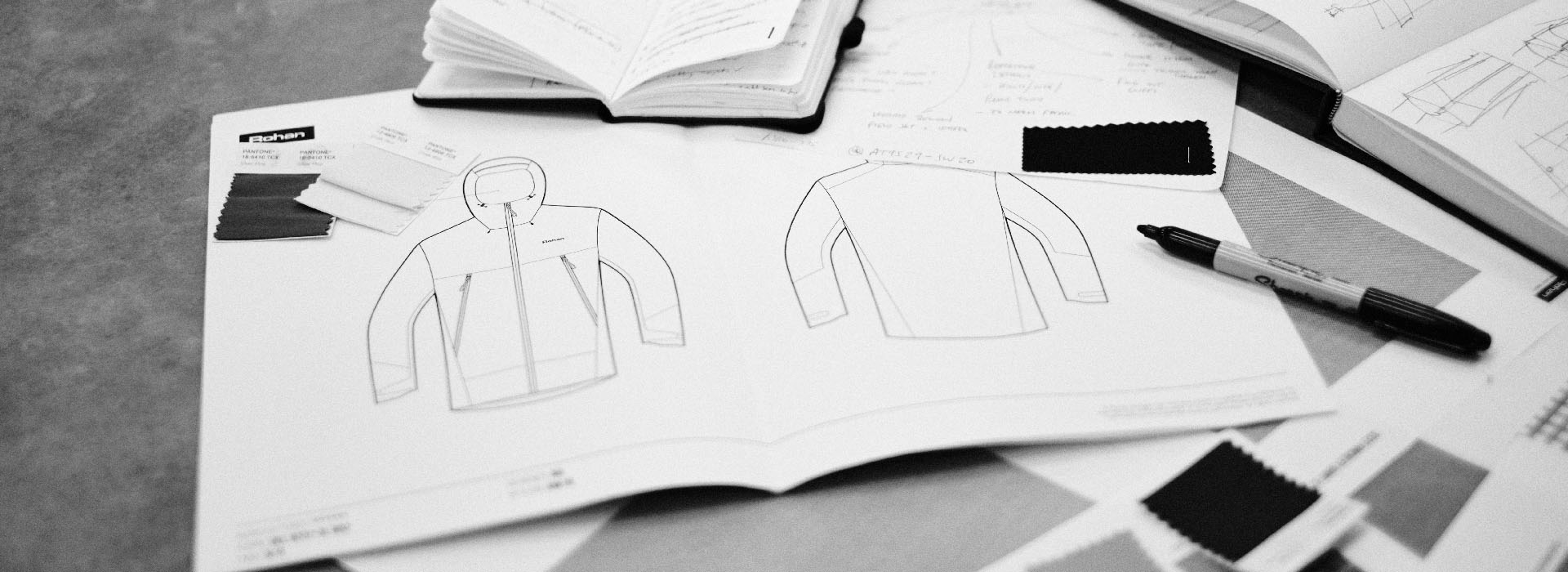

An interview with Rohan’s product design team.

It’s not every day we reveal the inner workings of Rohan. But when so much technical design and development goes into each pair of our trousers, we felt it only right that we shared.

What’s your background and experience? What do you bring to the Rohan team?

Through school I did design, design technology, graphics and art. I just love drawing basically.

I went to Loughborough University and studied industrial design, and whilst there I did a year out working for a motorcycle company. This was massively eye-opening for me, designing gloves and seeing where stuff was made.

After graduating, they hired me back full time as the clothing and accessories designer. Thinking about it, it was a really good bridge as it’s all about function with that sort of clothing - very protective, safety comes first, and then you can start to think about styling. After three years there I started at Rohan, and I’ve been here for seven and a half years now. So, it’s been quite a journey!

What makes Rohan trousers special?

We were the original innovators of outdoor clothing in the UK, this all started with trousers and still is the core of the range for us - the true DNA of the brand. The innovation continues today with every new trouser we design and develop, we are always striving for the next and better version. This is one of the most exciting aspects and challenges about design!

The first step is to put ourselves in the customer’s shoes: who is going to be wearing the trousers? What are they going to be doing? What do they aspire to do in them? These are some of the questions we continuously ask and challenge ourselves with.

Once we can answer these questions, the design process begins and it is always to produce the best product for the end use. Fabric selection is a huge part of this, and goes hand in hand with design. For instance, we have the District Chinos in the range that are produced from a specially selected and developed fabric. This feels and looks like a luxurious cotton, but has the added benefits of stretch, increased durability and a concealed elasticated waistband for extra comfort.

It's all of these details and thought that makes our trousers special.

How does this benefit customers?

I think there are probably two main benefits.

The first is whatever the customer is doing in the trousers, or is aspiring to do, they can achieve it. So, if that’s hiking, we have a trouser which has stretch in key areas, abrasion panels if you come across rocky terrain, all the pockets you need for valuables and other details which have gone into the design.

The other main benefit is that people want to know they are getting value for their money. They’re spending their hard-earned money after all. So it’s all about performance. That’s why our customers are so loyal and passionate. Our clothes are designed to perform.

Where does your team get their design inspiration from?

One of the great things is that everyone here is different. There are four of us, one’s recently graduated, so she’s coming in with brand new ideas, and another has worked in the performance industry so brings with her a totally different way of thinking. Combine that with my experience in the classic, more industrial product design industry, and our last member who has been more fashion-based, you have a great range of insights which help us build a product.

In terms of inspiration it often comes from personal experience. We’re all keen outdoors people, we travel a lot. It’s amazing where the inspiration can come from.

Rohan develops a lot of innovative materials for your trousers. How do you decide the materials that need to be developed?

This is probably one of the most challenging parts, because if you haven’t got the correct fabric, then you can’t have the correct design, which means you can’t have the correct product at the end. I think probably for the last two years because of everything that’s been going on in the world it’s made that even more difficult. So in terms of the timeline we work on, we are currently starting to design for Spring/Summer 2024, so we have to work near enough two years in advance of when we want to be launching the product and that’s because of the testing that goes on.

We use a lot of different fabric mills from all around the world, always picking specialists in the area we are designing for. For trousers, the mill we use produces materials with some fantastic stretch leg-wear qualities; really good performance, high abrasion. We talk to these specialists but then it’s up to us as designers to have the knowledge to select the correct fabrics, because if we choose something that’s too lightweight or too heavy it’s not going to work for the product.